Driver Vehicle Standards Agency

The types of load in this section are listed in alphabetical order.

Abnormal loads are generally large or heavy. There are specific rules for transporting abnormal loads to make sure that the load is restrained properly and keep other road users safe.

You must secure abnormal loads with a combination of physical restraints to movement such as:

- bulkheads

- chocks

- cradles

- lashings

The load must be stable on the load bed without lashings.

The operator and consignor must agree on the loading and securing scheme before transporting abnormal loads. If you are an operator or consignor, you must give your drivers or loaders appropriate training on how to load and secure unusual load types if they secure abnormal loads.

You must provide clear instructions on:

- suitable methods of loading and securing for each load type

- how to check tension in the lashings at regular intervals

- what to do if the load shifts during the journey

You must ensure that the load complies with Road Vehicles Lighting Regulations 1989 (SI No 1796) if it obscures:

- obligatory lights

- re?ectors

- rear markings

- registration plates

You should secure hay and straw bales carried on vehicles or open trailers using:

- webbing ratchet straps that pass over the top of the bales and additional strapping at the front and the rear of the load

- rated nets or tarpaulins

- strapping over the top of an empty pallet (or similar items that spread the forces) placed on top of the bale to help distribute the force of the straps

Wider lashing straps can help to spread the force over the load, which can prevent it being damaged or cut into.

You must use at least one strap per bale or row of bales with two straps per row at the very front and rear of stacked bales.

You must make sure that hay or straw does not become loose during transport. It could cause a hazard to other road users.

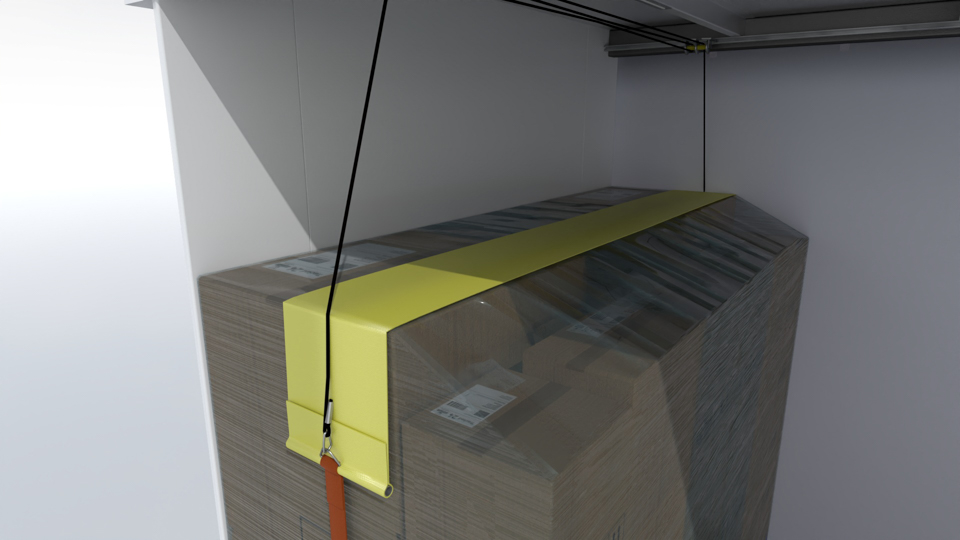

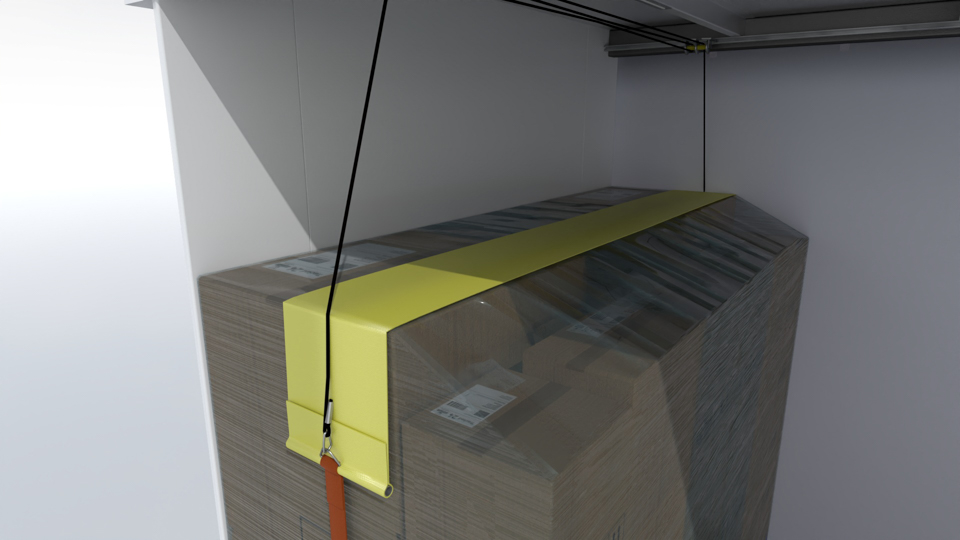

When transporting boxes you should:

- place them against the headboard or within 30 cm of it if possible, and secured using webbing ratchet straps if carried on open trailers

- use additional strapping at the front and rear if the boxes are stacked

- not stack boxes more than 3 on top of each other

Wider lashing straps can help to spread the forces over bales and boxes, as loads like this can be damaged or cut into by traditional lashing straps.

You should secure bulk bags carried on open vehicles by:

- using rated nets or tarpaulins

- strapping over the top of an empty pallet placed on top of the bag to distribute the force of the straps

- using wider lashing straps to distribute the force over the load

You must:

- use at least one strap per row

- cover any open bags if the securing method does not prevent the contents spilling or blowing out

You must secure construction products, like bricks and blocks, to the vehicle. Stacks of these products must be stable without lashings.

You should load them against the headboard if possible, or within 30cm of it if not.

One frictional lashing over each row will usually be enough for most loads.

If the load is higher than the headboard, you should use at least 2 frictional lashings over the front row of the load to create a bulkhead.

You must:

- secure the last row with 2 frictional lashings

- use a frictional lashing to prevent sideways movement if you use diagonal lashing (cross strapping) to create a rear bulkhead and stop rearward movement

If you use lashing straps to create a rear bulkhead, make sure that the lashings do not go under the base of a pallet used to carry the product. The lashing must go round the load and attach to the vehicle chassis.

If you are transporting construction products on pallets, you must secure them to the pallet to form a single unit before securing the

Related Articles

Comments

Write a Comment

Ministerial Departmental News

- PM's Office, 10 Downing Street

- Cabinet Office

- Department for Business, Innovation and Skills

- Department for Communities and Local Government

- Department for Culture, Media and Sport

- Department for Education

- Department for Environment, Food and Rural Affairs

- Department for International Development

- Department for Transport

- Department for Work and Pensions

- Department of Energy and Climate Change

- Department of Health

- Foreign and Commonwealth Office

- HM Treasury

- Home Office

- Ministry of Defence

- Ministry of Justice

- Northern Ireland Office

- Scotland Office

- Wales Office

- See all departments